Metal Stamping and Forming

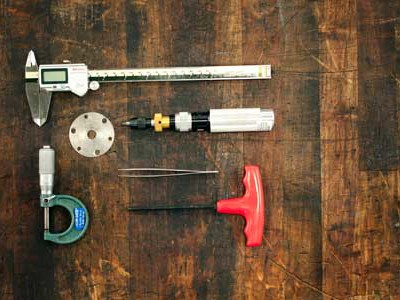

TOOL AND DIE CAPABILITIES

The Greene Group’s die shops are among the best-equipped in the United States, and are staffed with some of the most knowledgeable and experienced toolmakers in the metal fabrication industry.

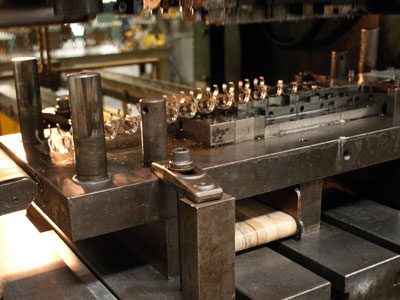

Progressive dies which maintain precise stampings of over 100 major and minor dimensions are among the Greene Group’s state-of-the-art die-making capabilities.

METAL FORMING SPECIALISTS FOR A VARIETY OF INDUSTRIES

The Greene Group of companies is a major supplier to leading industrial manufacturers across the country, providing metal parts manufacturing and fabrication services for a wide range of products.

Manufacturers nationwide rely on Greene Group’s reputation for the highest product quality and conformance to specifications.

COMPREHENSIVE STAMPING TECHNOLOGIES

• Progressive die

• Deep draw

• Short Run

• Cold Heading

FACILITIES AND EQUIPMENT

• Complete tool and die workshops and veteran toolmakers

• Wide range of punch presses – 10 – 400 tons, 2 – 600 parts per minute

• Cold heading and heat treatment

• Welding center – seam, spot, MIG, TIG and ARC

• State-of-the-art CNC machine shop, including Wire EDM and CNC spring coilers

• Mill slitter for in-house stock conversion

VARIED STOCK OF METALS

• Carbon steel

• Stainless steel – 301, 316, 410, 420

• Aluminum

• Copper

• Tungsten alloys

• Brass

• Clad materials

• Titanium

• Kovar

• Molybdenum